Which of the Following Actions Would Help Prevent Chemical Hazards

A vaccine is only available for which of the following major bloodborne pathogens viruses. Which of the following is an example of a.

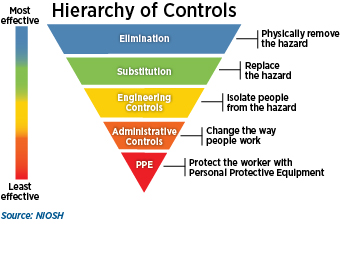

Safety Management Hazard Prevention And Control Occupational Safety And Health Administration

If removal is not feasible enclose the hazard to prevent exposure in normal operations.

. 1 Store chemicals away from food utensilsand equip. Wear gloves masks or other protective devices to. The potential hazards of the chemical such as health fire and environmental.

Extending ones arms overhead and taking deep breaths can relax the muscle. If not already fire polished fire polish the end of the glass to be inserted. The following practices will help prevent accidents.

Post an example of a conflict that can arise during a workout how you can recognize it and how you can resolve it. Controlling Chemical Hazards. Read the instructions for how to use the chemical properly.

The goal of the Chemical and Biological Hazard Prevention CBHP field is to help prevent occupational diseases and adverse health effects and to improve and maintain the health and well-being of workers exposed to chemical substances and biological agents. It provides useful information on the chemical hazards advice on safe handling use and storage and the emergency measures to be followed in case of an accident. If feasible design the facility equipment or process to remove the hazard or substitute something that is not hazardous.

Providing adequate ventilation washing your hands minimizing exposure to chemicals maintaining equipment to prevent leaks and breakdowns and using personal protective gear like Black Stallion chemical-resistant gloves all minimize the effects of dangerous chemicals. Select controls to protect workers during nonroutine operations and emergencies. There are three main Routes of Entry Absorption Inhalation Ingestion.

Overcrowding of shelves with storage containers can easily cause a chemical spill. Water may be sufficient but glycerol is a better lubricant. How to work safely with the chemical product.

Chemical hazards can be defined as non-organic substances which are dangerous for human life. Shelves should also be fitted with raised edges or lips that help prevent chemical containers from slipping off the surface. Damage to equipment and disruption in service.

Chemicals which should be considered include color additives direct food additives indirect food additives prior. Which of the following actions can help prevent exposure to bloodborne pathogens. 4 Label chemical containers when transferring a chemical to a new container.

The action of storing chemicals in a separate area away from food will help prevent chemical hazards Option a. Once the hazards involved in the handling and use of chemicals are identified the next stage is to put control measures in place. This includes Elimination- Options which get rid of the hazard altogether.

Make sure the diameter of the tube or rod is compatible with the diameter of the hose or stopper. Chemical hazards or at least reduce exposure to a low level. Prevent Overcrowding in Chemical Storage Units.

Substitution- Replacing a hazardous chemical with a less hazardous one wherever possible. The safe working load SWL should be clearly marked on each shelf. Mitigation actions are generally evaluated against multiple criteria including effectiveness practicality and cost.

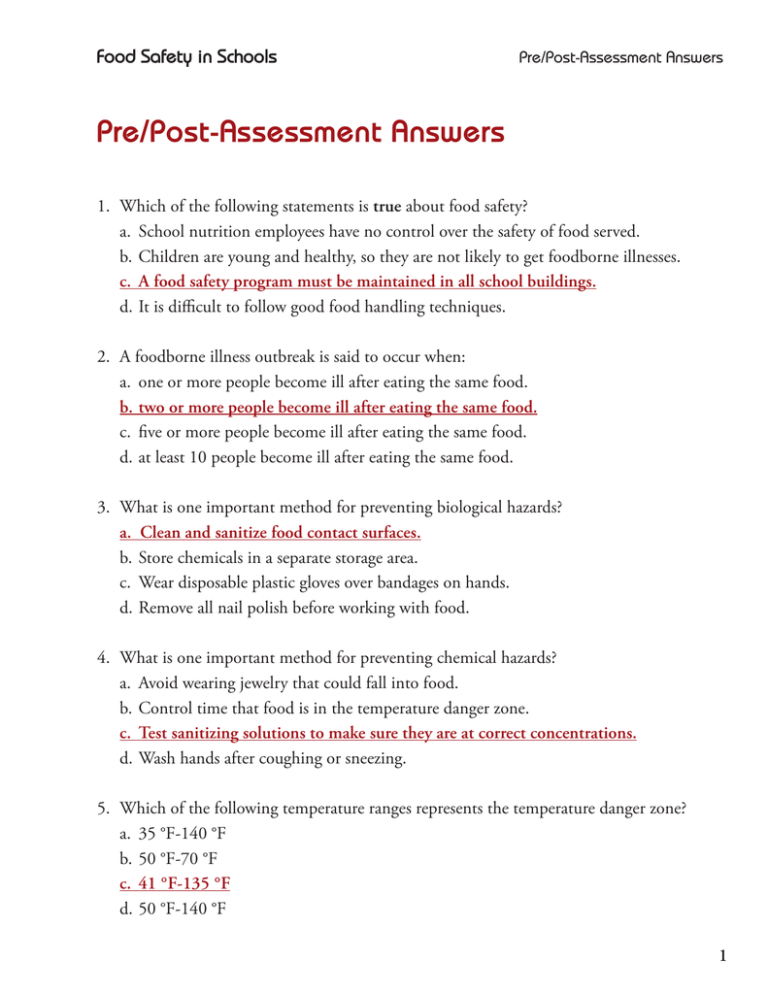

It is well known that exposure to chemical hazards may lead to negative health effects or even cause death. Ask your employees to examine the chemical containers. There are four primary categories of food safety hazards to consider.

Correct any existing or potential chemical hazards. A mitigation action or project can reduce or eliminate the. Storage during use cleaning agents sanitizers prior to receipt in ingredients and packaging materials upon receipt of materials during processing and prior to shipment of product.

Biological chemical physical and allergenic. Where complete enclosure is not feasible establish barriers or local ventilation to reduce exposure to the hazard in normal operations. NIOSH leads a national initiative called Prevention through Design PtD to prevent or reduce occupational injuries illnesses and fatalities through the inclusion of prevention.

Implement selected controls in the workplace. Chemicals can be safer to others but to some sensitive workers even the most common solutions can cause illness skin irritation or breathing problems. Chemical hazards should be addressed in steps in the production process.

Follow up to confirm that controls are effective. 5 Only use lubricants that are made for food equipment. Keep the work area well ventilated.

2 Follow mfgr directions when using chemicals. And examples to develop mitigation projects for various natural disasters are provided on the following pages. Following this hierarchy normally leads to the implementation of inherently safer systems where the risk of illness or injury has been substantially reduced.

If your hobby involves the use of chemicals you can reduce your chances of exposure in several ways. For example you could post that a side stitch a sharp pain under the ribs can cause conflict while running. Safety data sheet SDS A safety data sheet SDS is a document that must be provided to you with all hazardous chemicals.

The safety data sheet can help reduce the risks but not the underlying hazard of the chemical in your workplace. The preferred approaches are innovation generating new knowledge conducting critical. Chemical Hazards The methods in which chemicals enter the body are called routes of entry Understanding these various routes of entry is necessary to prevent exposure to hazardous chemicals.

If you find any unlabeled chemicals show your employees how to properly dispose of them and explain how the bottles should be labeled. Understanding the risks associated with each can dramatically reduce the potential of a foodborne illness. Each have their own unique characteristics but all can be avoided through a robust food safety management system FSMS.

Develop and update a hazard control plan. Chemical hazards are present when a worker is exposed to any chemical preparation in the workplace in any form solid liquid or gas. A person conducting a business or undertaking must.

3 Be careful when using chemicals while food is being prepared. Show your employees where chemicals should be stored to prevent cross-contamination. The best way to relieve it is to stretch the cramping muscle.

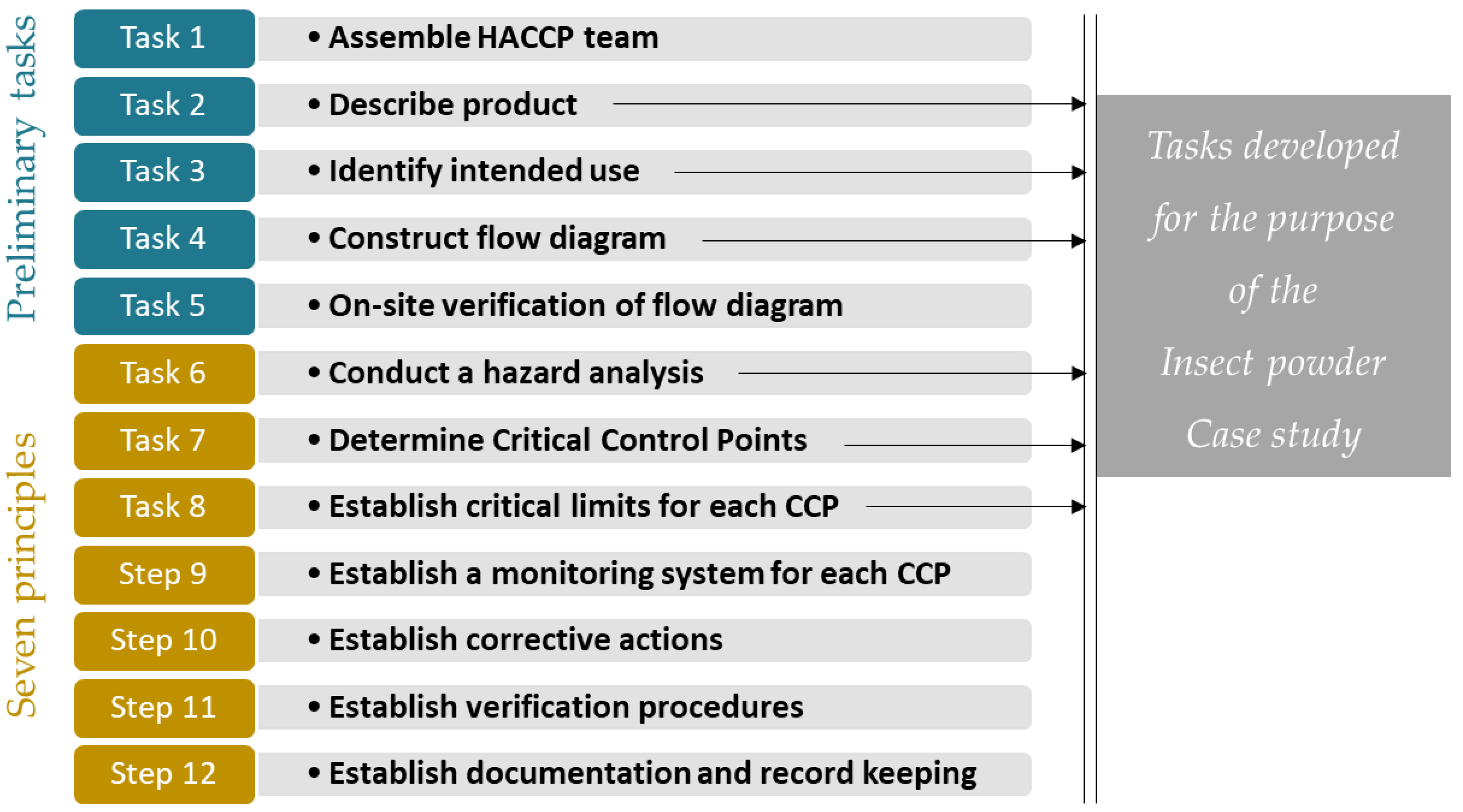

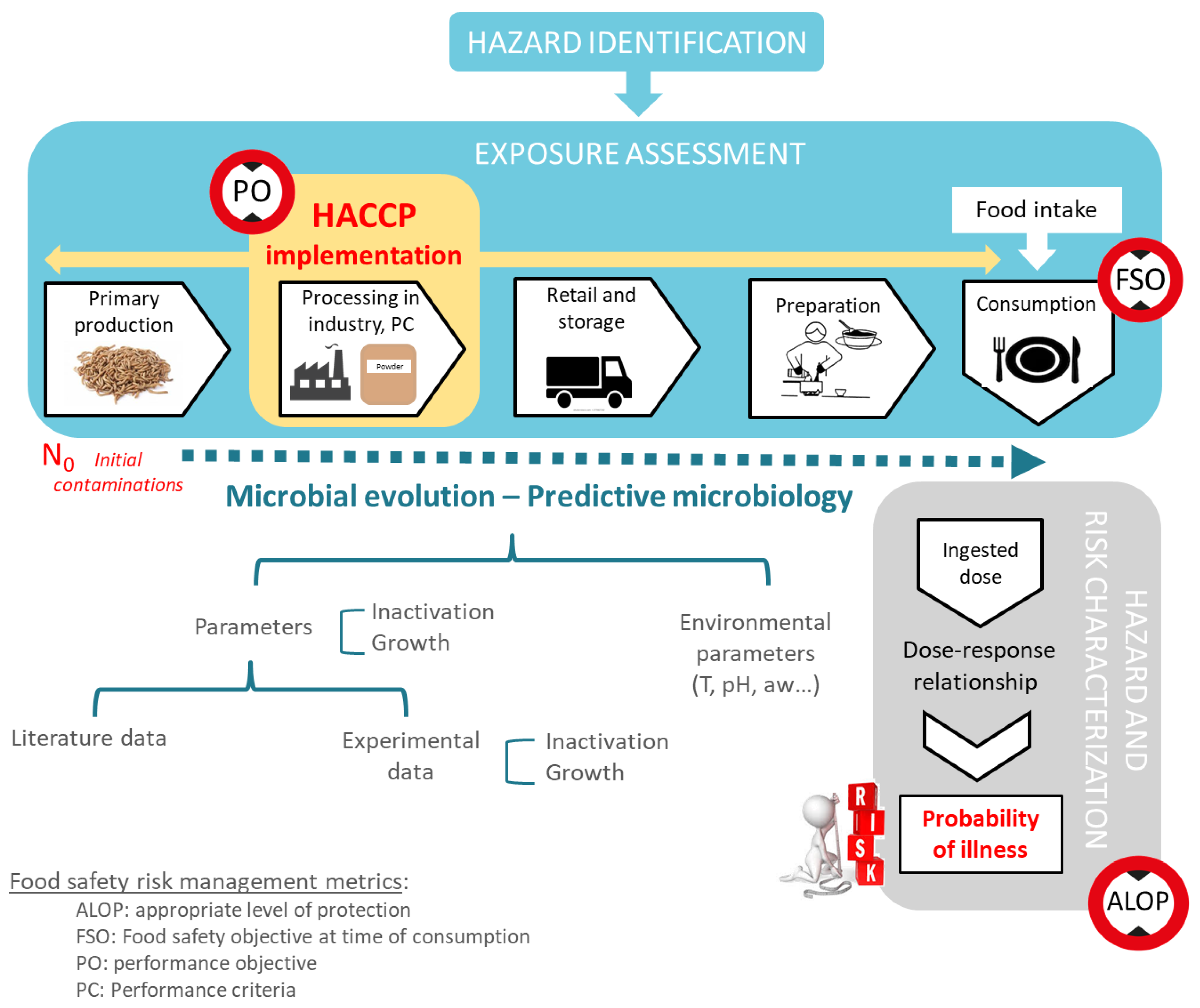

Foods Free Full Text Control Of Biological Hazards In Insect Processing Application Of Haccp Method For Yellow Mealworm Tenebrio Molitor Powders Html

Community B Docx Ati A Community Health Nurse Observes The Accumulation Of Garbage At A Studocu

European Flag European Commission Brussels 14 10 2020 Com 2020 667 Final Communication From The Commission To The European Parliament The Council The European Economic And Social Committee And The

Laboratory Hazards Chemical Physical Biological Hazards In The Lab

How Can Occupational Safety And Health Be Managed Labour Administration And Inspection

Foods Free Full Text Control Of Biological Hazards In Insect Processing Application Of Haccp Method For Yellow Mealworm Tenebrio Molitor Powders Html

Community B Docx Ati A Community Health Nurse Observes The Accumulation Of Garbage At A Studocu

Comments

Post a Comment